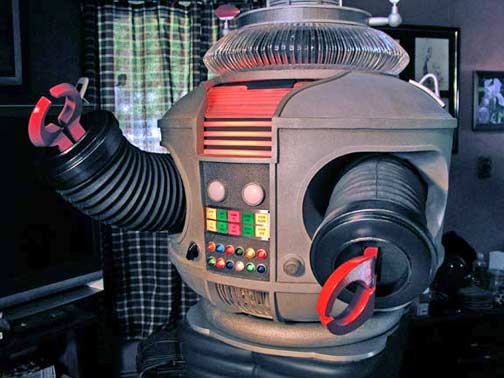

The

arm is made from a piece metal dryer duct. In a compressed state it

doesn't look too bad, and at 10 bucks the price was right. The wrists

are wooden (with some bondo on the tapered front part). The claws are

also wood, painted red/orange, and coated with polyurathane. I added

a quarter moon piece of mat board where the arm goes into the socket

to simulate the rubber flange and painted it to match the arm color.

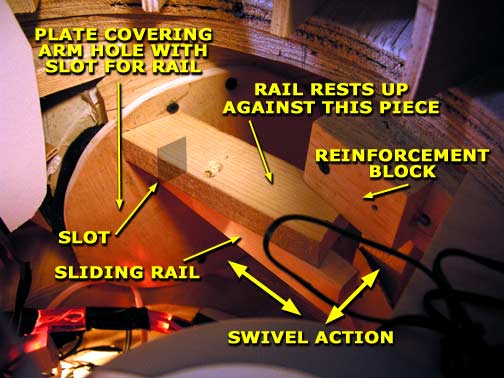

The whole thing is supported inside by a wooden piece and bolted to

the interior frame.

Future plans include metal claws and connection to a portable generator capable of generating 40,000 volts like a tesla coil. It's a great thought, you have to admit.

Future plans include metal claws and connection to a portable generator capable of generating 40,000 volts like a tesla coil. It's a great thought, you have to admit.

UPDATE

My

original claws really sucked. There was no bevel, they weren't thick

enough, they were really off. Much better now.

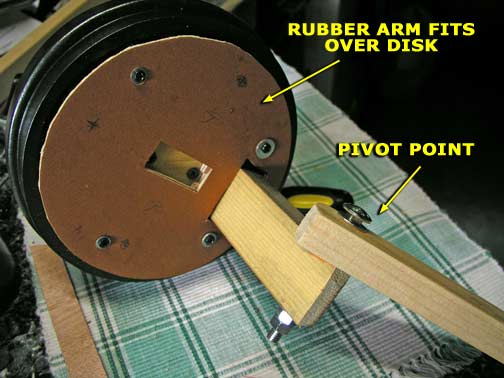

I have also installed rubber arms. The wrists have been repainted with a charcoal gray lacquer.

I have also installed rubber arms. The wrists have been repainted with a charcoal gray lacquer.